Machines We Use

We build your commercial kitchen equipment Goa in our own workshop. We don’t just put parts together. We use strong materials and modern machines to make equipment that lasts.

The Machines That Make It Possible

Good machines mean a better product. Here are the tools we use to build equipment you can trust.

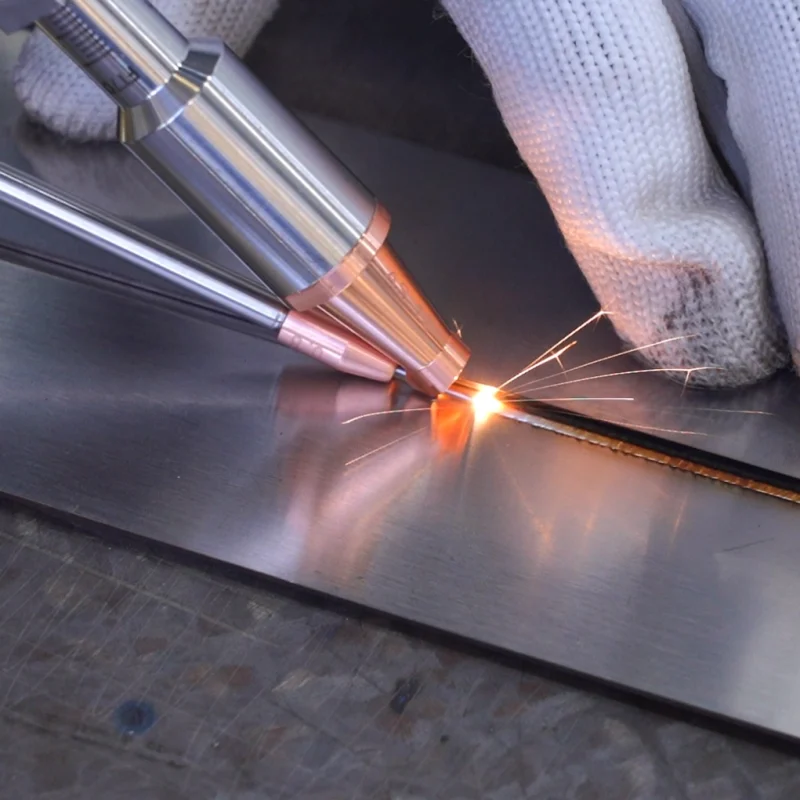

Laser Welding

This method uses a focused laser beam to make the weld, creating a very strong, clean joint quickly and with less heat.

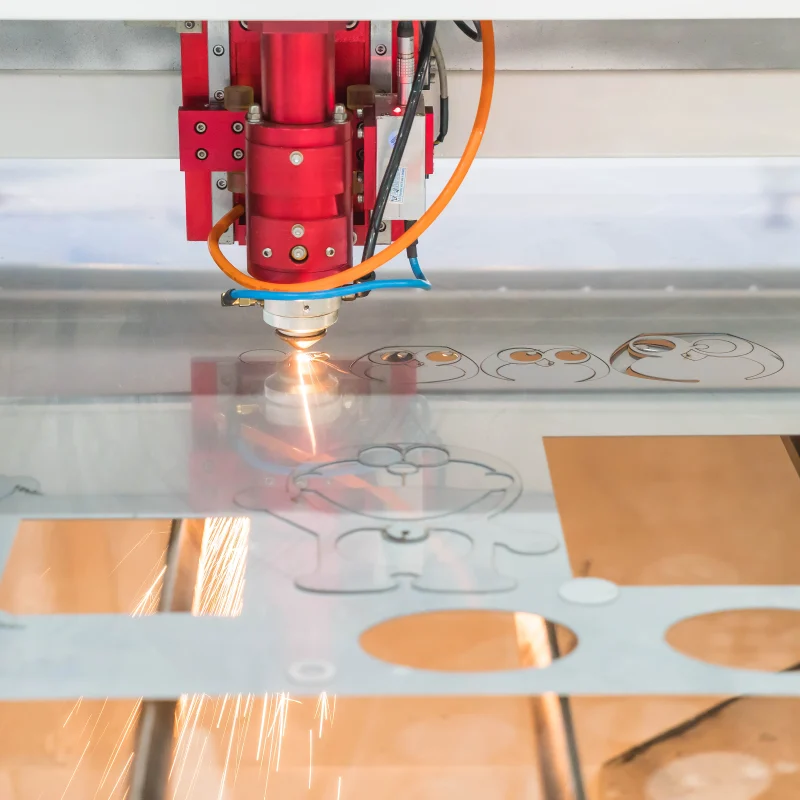

Laser Cutting

Our laser cutter cuts the sheet clean. Each part fits together perfectly.

CNC BEnding

This machine bends sheet with perfect accuracy every time. It gives us strong, straight frames and panels that fit just like they should.

TIG / MIG Welding

We use both TIG and MIG welding techniques. TIG gives clean, precise welds for visible areas. MIG provides fast, strong welds for structural parts.

COMPUTER AIDED DRAFTING (CAD)

For custom work, we design on computer first. This lets us show you exactly how it will look and work before we build it.

We Use the Right Materials

As leading commercial kitchen manufacturers in Goa, we source the best materials. For our stainless steel sheets, we use trusted brands like JSW and Jindal to ensure quality from the start.

At ASMW, we keep two steels in stock. One is meant for all the clean surfaces in your kitchen, and a completely different type is used for building the strong frames and supports.

Food-Grade Stainless Steel (SS)

This is best for surfaces like sinks and tables. It stays looking new because rust and stains don’t stick.

Mild Steel (MS)

This material is for support zones like stands and high-heat equipment. It’s robust, and we finish it with a protective coating so it lasts.

Custom Fabrication for Your Exact Space

Need a solution for a tricky corner or an unusual layout?

We can fabricate it.

Tell us your specifications for custom stainless steel fabrication, and we will build equipment to fit your kitchen perfectly. Our workshop is set up for custom work.

Durability You Can See

The quality is in the details. We weld carefully to make strong joints. We finish the surface smooth so it cleans easily. Our build is sturdy. It handles daily kitchen work without coming loose.

FAQs

How long does it take to make custom equipment?

It’s different for each project. A small fabrication job is done in days. Big projects need a few weeks in our workshop schedule.

Can you handle a large hotel kitchen project?

Yes, our workshop handles big projects. We can manufacture all the stainless-steel work tables and custom pieces needed for an industrial or hotels.

How do you maintain consistent quality?

Our machines provide consistent results, and our workers check each piece. This system ensures good quality every time.

What's the advantage of your CNC bending machine?

The CNC machine provides precise, consistent bends. This ensures all frame pieces match perfectly for assembly.

Can you repair old rusty equipment?

We can often build new sections to replace rusty parts. This is usually better than trying to fix badly corroded metal.